Buying replacement belts for your pastry or dough sheeter and making sure they fit properly can be more difficult than you think. As second-hand dealers, we have a lot of experience sourcing and even making the parts we need in order to repair and refurbish old equipment. Unlike with moulder belts and many other spare parts, you can’t simply provide a make and model number and get a sheeter belt that will fit your machine.

Over the life of a sheeter, its table sizes can change significantly. Major repair work or customisation can involve completely replacing one or both tables entirely. Even small things like adjusting the table tension over time can significantly change the length of the tables without you even realising. Ordering sheeter belts that were designed to fit your machine new (if you can even find them) doesn’t necessarily mean they’ll fit. So what can you do to make sure you’re not wasting money on belts that won’t fit?

Custom-Made Sheeter Belts

The only way to truly ensure that any new belts for your sheeter will fit is to have them custom made for your machine. By purchasing custom sheeter belts you have full control over the fit and material ensuring you get exactly what you want. At Australian Bakery Equipment Supplies, we work closely with premium Australian belting manufacturers to ensure you get the best food-grade belts for your sheeter.

Measuring Your Sheeter Belts

Because one size won’t fit all you’ll need to measure your sheeter in order to order a custom belt. This process is straight forward but there are a few things worth knowing to make sure you can get accurate measurements quickly and easily.

1. Check The Tension Adjusters

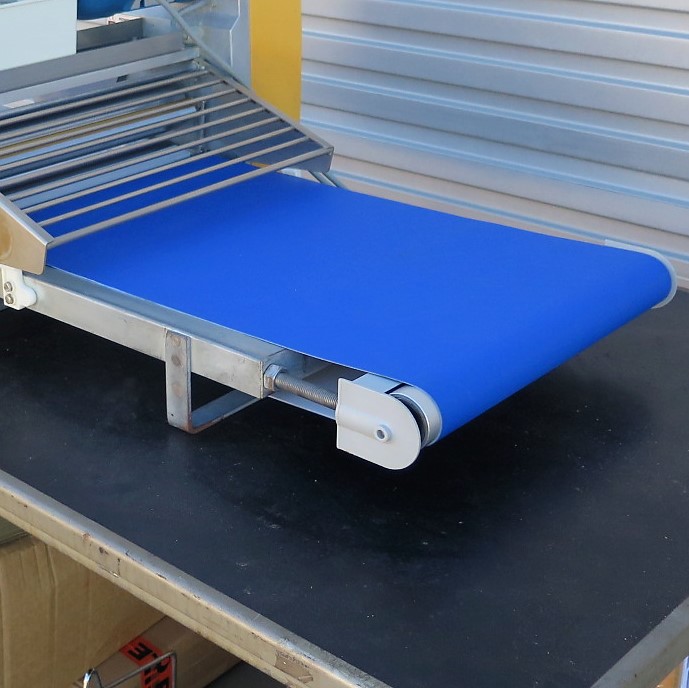

At the end of each table on your sheeter, there should be a tension adjuster. This mechanism allows you to adjust the position of the end roller, lengthening or shortening your overall table length. As a sheeter is used and the belts begin to stretch with age and use the adjuster can be used to easily increase the tension on the belt to ensure the machine runs properly with correct belt tension.

Some adjusters only allow for small changes, while others can significantly increase the length of the table. Check the tension adjusters to ensure they are not fully extended and reset them to a shorter position. This will make fitting the new sheeter belts easier and increase the lifespan of the belt as you once again have room to lengthen the tables when the belts begin to stretch.

2. Getting an Accurate Measure

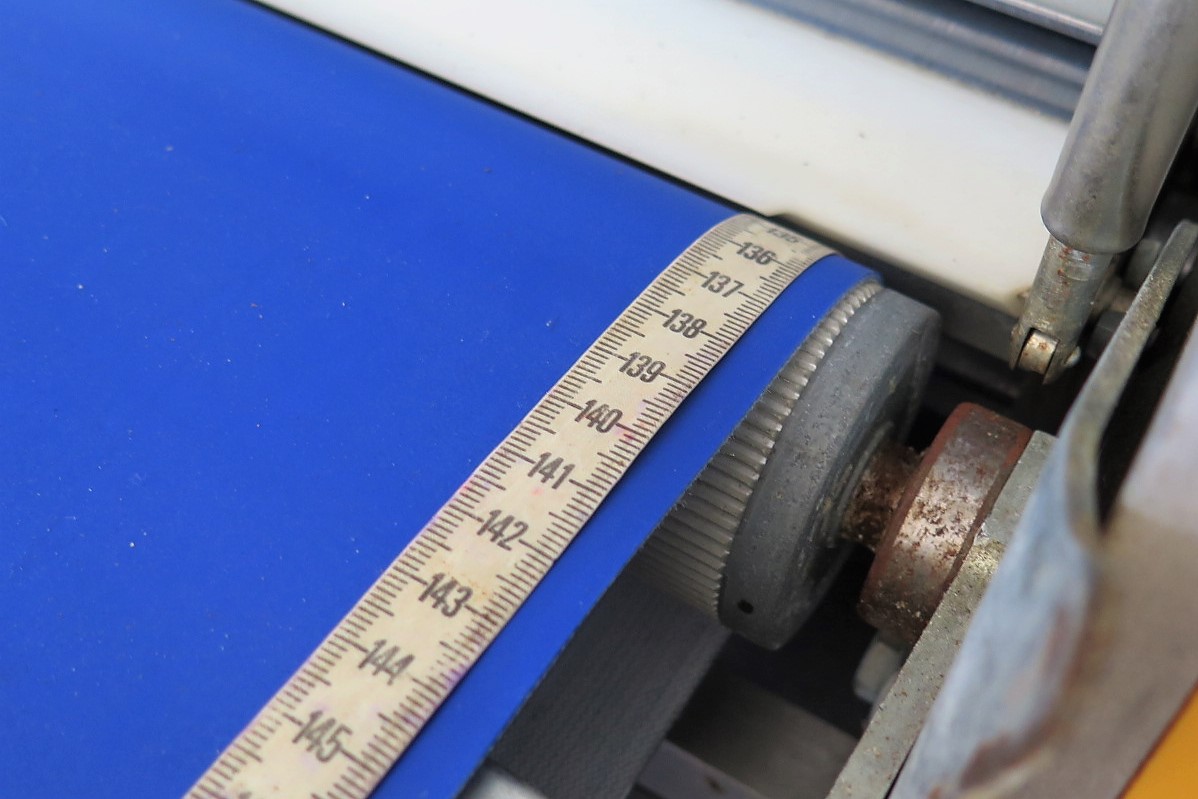

Using a soft and flexible tape measure is the easiest way to measure your sheeter belts. If you don’t have a suitable tape measure a piece of string of similar will work as well. Ensure whatever you’re using to measure is soft, flexible, and doesn’t stretch.

Lift the guard to access the internal end of the table. Depending on the design of your sheeter, you may need to remove the scrapers as well to get a clear space you can run the tape. Thread your tape measure into the sheeter ensuring it is just wrapped around the table and not caught on any other parts. Watch out for bars, feet, and other obstructions on the underside especially. Note the measurement for the length of the belt. Then measure the width of the belt and repeat for the other table.

While the tables are generally the same length, slight differences can generally be accounted for with the tension adjusters. If your tables are significantly different lengths don’t worry, certain models and the age and repair history of the machine can all account for this. Make sure you label your measurements so you know which belt will fit which table when you receive your sheeter belts.

The Right Material for the Job

Food-grade belts can be made in a wide variety of materials to serve various purposes. Sheeter belts, moulder belts and conveyor belts are all made differently to meet the needs of users. When it comes to choosing the material for your belt there are two things to consider. First, what your existing belt is made of and second the kind of product you are working with. Knowing the material of your existing belts and thinking about the things you love or hate about them can help guide your choice.

Cotton sheeter belts offer easy dough release and are very common in dough sheeters. PVC belts are general all-rounders that get the job done at an affordable price. Polyurethane or PU belts are hardy and easy to clean with high abrasion and oil resistance. Cotton can also be blended with PU or polyester to create belts that are stronger than standard cotton sheeter belts.

How Australian Bakery Equipment Supplies Can Help

We can help you find the perfect new and replacement belts for your pastry and dough sheeters. We understand that the only way to get a perfect fit every time is to custom make sheeter belts for the machine. Whether you need a set of replacement belts for an old sheeter or need a different style belt for a brand new machine we have a solution for you.

If you’ve got special requirements or need some advice our experts are on hand to help. Contact the team today and experience the ABES difference.